High-Speed Automation of Microscopic Visual Inspection for 500 Items

Introduction to the Automation of Microscopic Visual Inspection Previously Conducted by Skilled Operators

The main challenge in this automation effort was the need to inspect a large number of small components at high speed. Each specimen requires inspection at over 500 locations, covering a wide range of defect types—from millimeter-scale metal bending to micron-level solder irregularities.

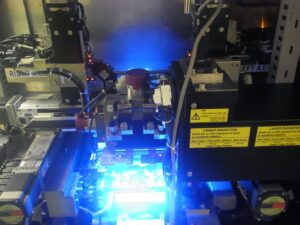

To meet the requirement of sub-second inspection per item, the system performs high-speed image acquisition during motion. This necessitated solutions for issues such as insufficient illumination and the processing of large-scale image data with high accuracy and speed.

The complexity of visual design and composition

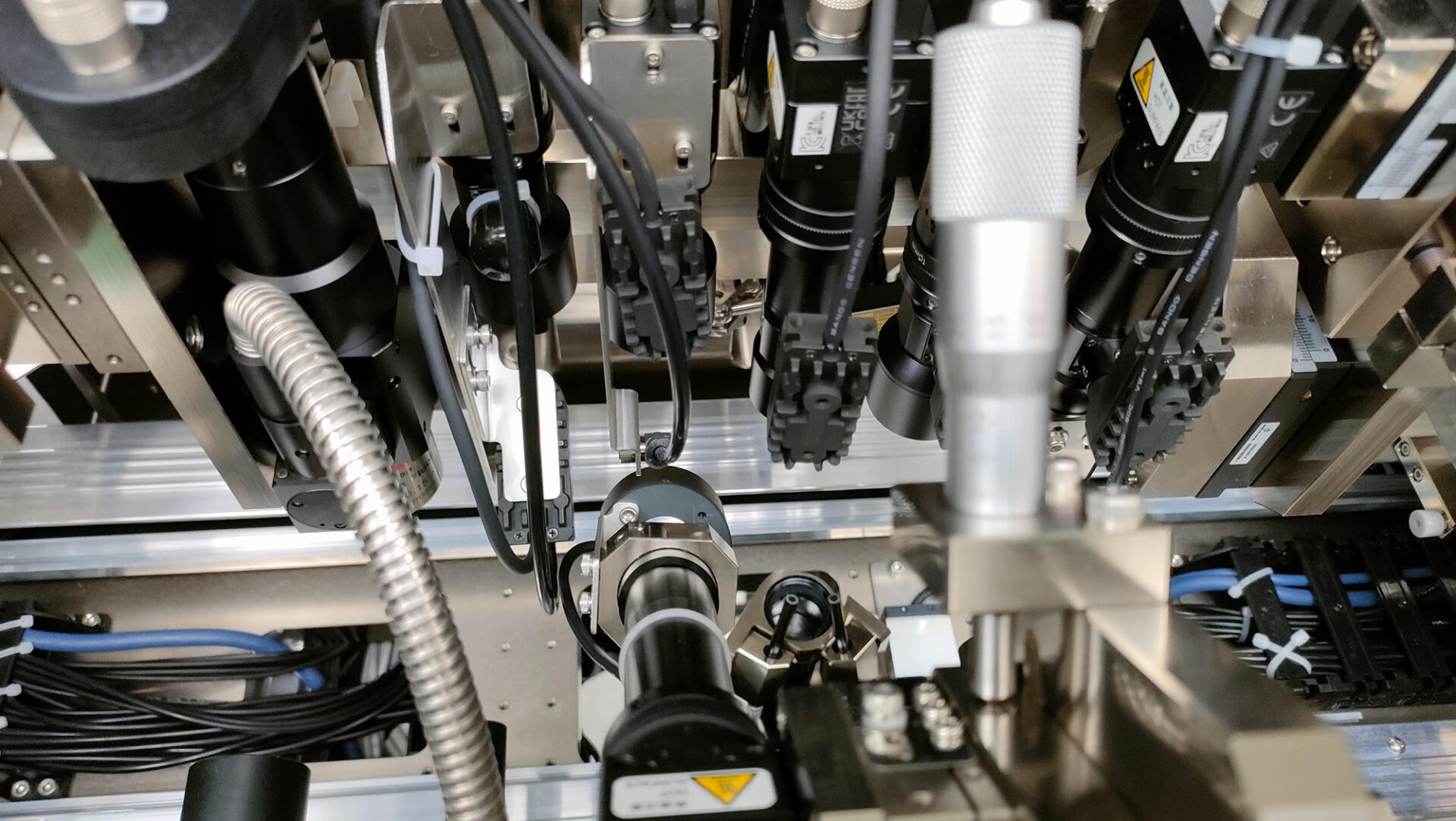

This system utilizes 15 area cameras, each covering a specific field of view, to capture images of numerous workpieces as they pass by. Each camera triggers its shutter in synchronization with the workpiece position, with an extremely short exposure time of approximately 70 microseconds. To compensate for limited exposure time, various techniques have been employed to enhance image brightness.

Even within the same field of view, different inspection targets may require different lighting conditions. In such cases, the system switches illumination settings and performs additional image captures to ensure optimal visibility for each target.

Ultimately, the accuracy of image-based inspection depends on how well the image expresses the key features required for judgment. Creating such high-quality images under strict time and lighting constraints is one of the most critical and challenging aspects of the system design.

Efficient Management of High-Volume Image Acquisition and Processing

This system employs 15 area cameras, each precisely synchronized to capture images as numerous workpieces pass through their respective fields of view. In some cases, multiple images are taken under different lighting conditions within the same field to accommodate varying inspection targets.

All timing signals for camera triggering and lighting control are managed through encoder feedback, ensuring accurate synchronization between the moving workpieces and the imaging system.

Each camera generates a massive volume of image data every second, placing significant demands on the image processing pipeline. Initially, ultra-parallel processing was implemented within the device to handle this load. However, as AI-based judgment and analysis were introduced, the onboard processing capacity reached its limits.

To address this, the system now performs full-scale image acquisition first, followed by comprehensive image analysis on a dedicated external server. This architecture ensures both high-speed operation and reliable inspection accuracy.