The system is designed to measure the angular posture of a specimen and automatically align it to a predefined target orientation.By integrating high-resolution imaging or sensor-based feedback with precision motion control, the device enables accurate and automated posture correction.Users can configure control parameters including adjustment axes, angular thresholds, and response dynamics to suit specific operational needs.

This automated system is designed to transport specimens to a measurement stage, where their orientation angles are precisely measured and adjusted.

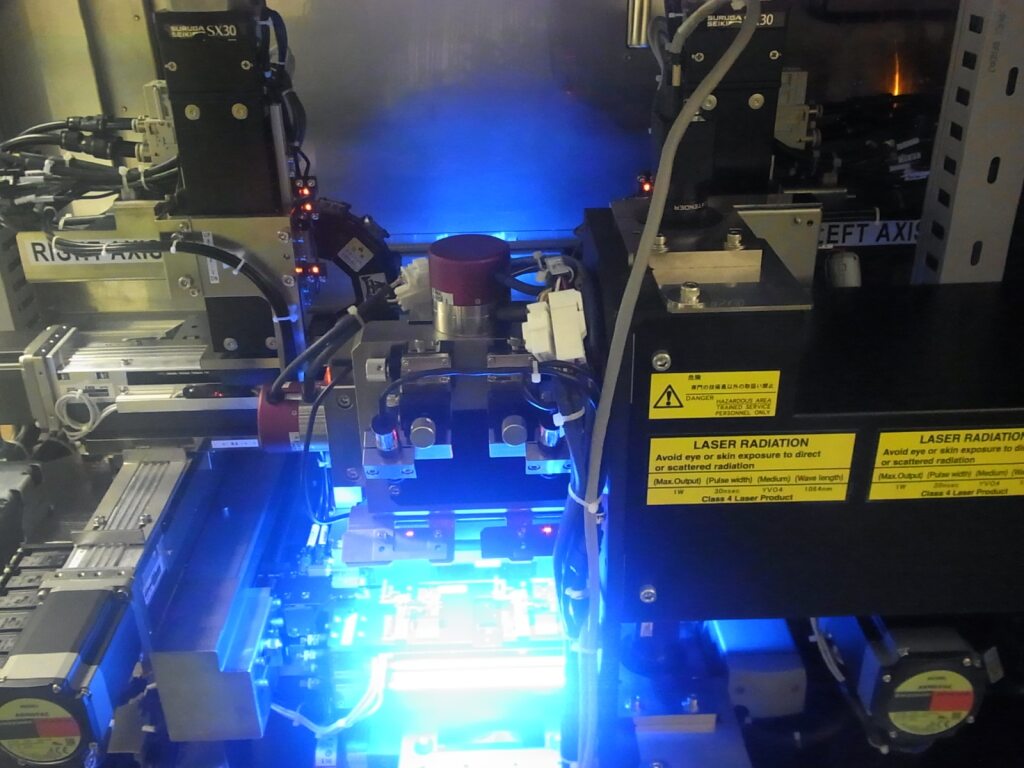

Using laser-based analysis, the system calculates the optimal irradiation position and intensity required to align the specimen with a predefined target angle. Laser irradiation is then applied to achieve the desired posture correction.

To enhance measurement resolution, a pinhole is positioned between the laser pointer and the specimen, reducing the laser spot size for finer detection.

For improved cycle time, the system incorporates dual transport lines and dual measurement stages, enabling simultaneous processing of multiple specimens—one undergoing adjustment while the next is being prepared.

Laser Output

While standard laser marking systems operate with laser outputs in the range of several watts, our system utilizes a low-power laser (hundreds of milliwatts) for posture angle control.

By conducting optical design in-house, we have successfully focused the laser beam to a spot size of several tens of micrometers, enabling precise processing even at low output levels.

To achieve accurate laser processing, the system includes a position correction function that compensates for deviations between the expected and actual target positions. This correction is based on image recognition or sensor feedback and is applied in real time before laser irradiation.

The system incorporates a coaxially aligned observation camera with the laser to enable precise position correction through image processing.

This configuration minimizes the impact of specimen-to-specimen variation, ensuring consistent and accurate laser irradiation.

Furthermore, laser processing patterns can be intuitively registered using camera-based imaging, simplifying the setup process and enhancing usability.