Nano-Scale Gap Measurement

The gap between the magnetic head and the surface of a spinning HDD disk is extremely small—ranging from just a few nanometers to several tens of nanometers—created by the airflow generated during disk rotation.

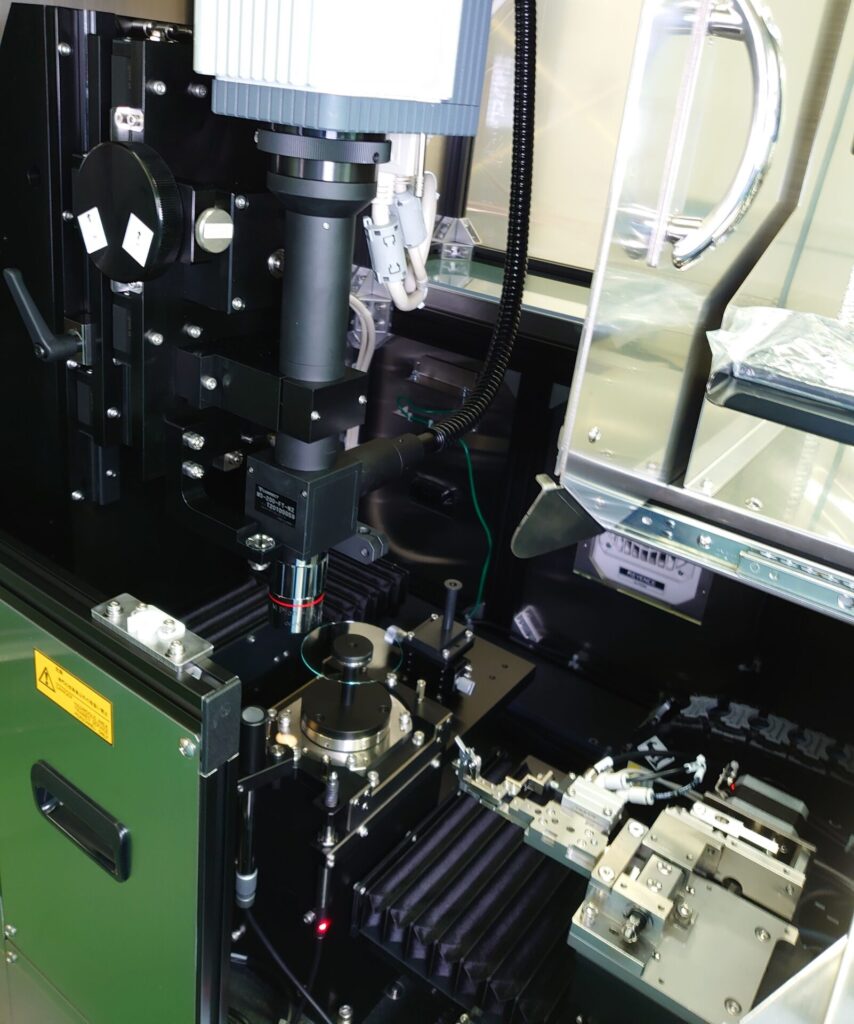

In our magnetic head flying height measurement system, the magnetic disk is replaced with a transparent glass substrate to simulate the airflow. The magnetic head is loaded onto the glass surface, and light is directed through the glass onto the head slider.

Due to the ultra-narrow gap between the underside of the transparent substrate and the surface of the head slider, the incoming light undergoes multiple reflections. These reflected light intensities are captured by a camera, and the system calculates the precise gap size based on the variations in light intensity.

Using high-speed imaging and optical analysis, the system performs a single-shot measurement of the magnetic head's flying attitude, including its height, tilt, and alignment. This approach significantly reduces measurement time while maintaining high precision.

The magnetic head flying height measurement system utilizes a 2D camera to capture the entire head slider.

Gap values are computed from the light intensity at each pixel, which reflects the multiple reflections occurring in the nanometer-scale gap between the transparent substrate and the slider surface.

From this data, a 3D map of the slider is reconstructed, enabling accurate assessment of its flying attitude, including tilt, curvature, and height distribution.

Measurement in Specialized Environments

To accommodate advanced testing requirements, the magnetic head flying height measurement system is equipped with a chamber that enables measurements under controlled environmental conditions.

These include vacuum operation, helium atmosphere substitution, and temperature-controlled settings ranging from high to low extremes.